Substrate plating prewash

Processing Details

- Washing

- Roughening

Degreases and cleans while simultaneously creating an optimal surface for plating adhesion.

Wet blasting simultaneously degreases, cleans, and processes the substrate surface, creating an optimal surface for plating.

Plating pre-treatment of substrates by wet blasting

Removes and cleans foreign substances such as residue and contamination from solder resist (SR) created during the manufacture of printed wiring boards (PWB) and printed circuit boards (PCB).

At the same time, it improves the adhesion of gold plating to prevent peeling and reduce adhesion defects.

Parts to be processed

- Printed Wiring Boards (PWB)

- Printed Circuit Boards (PCB)

- Films

- Foils

Processing Point

By degreasing and cleaning the substrate surface and processing the base at the same time, it is possible to create the ideal surface for plating.

Problems with conventional methods

- Since the material of the foreign matter attached to the surface is unknown, it is difficult to remove it with chemical etching such as pickling or organic solvents.

- When using chemicals, it is difficult to clean every corner due to differences in level, etc., resulting in uneven processing.

- Scratches on wiring are caused by contact during cleaning by the physical process.

- Composites are difficult to clean.

Treatment Processes

STEP

01

Formation and baking of solder resist (SR)

STEP

02

Wet Blasting Cleaning

STEP

03

Nickel-Gold Plating

STEP

04

External Processing

STEP

05

Next Process

Features of Wet Blasting

- Even thin resin films of several microns are free from deformation, tearing, and deterioration.

- Nano-anchors can be formed that do not affect conductivity.

- It is also effective in improving the adhesion of super-engineered plastics, which are called difficult-to-adhere materials.

(Super-engineered plastics: PPS, PEEK, PI, LCP, etc.) - Because it is a physical process that does not use chemicals, foreign matter can be removed from any material.

- There is no time dependence.

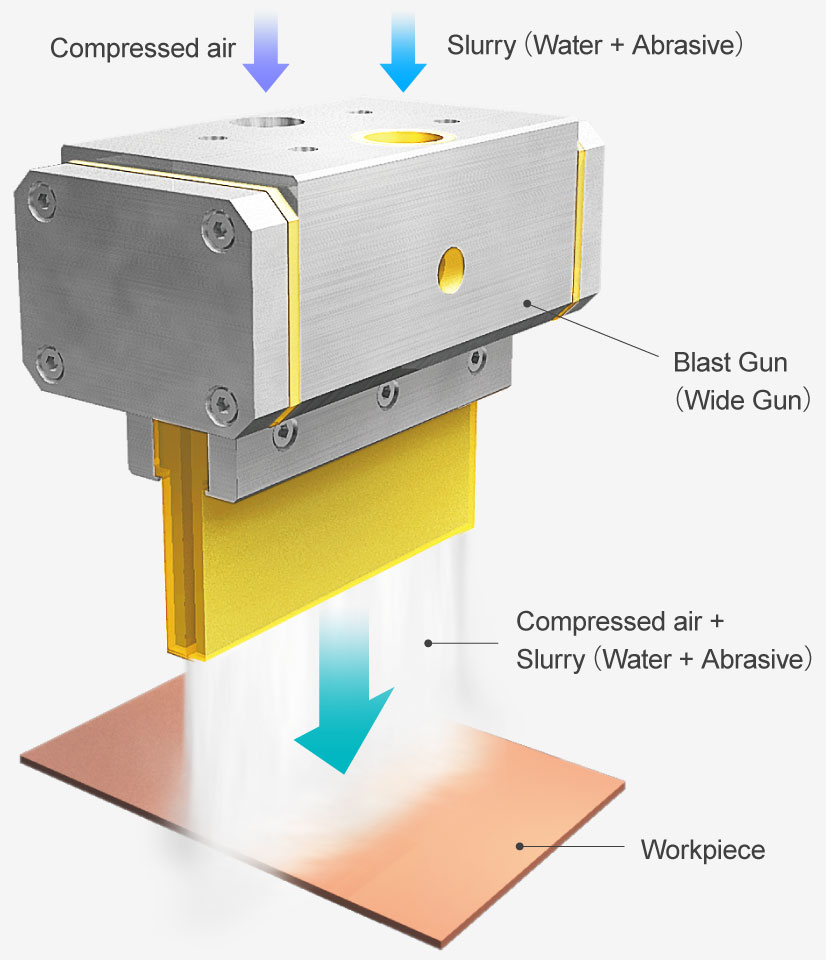

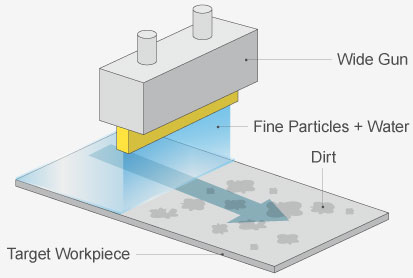

Image of Wet Blasting Cleaning

Powerful physical cleaning, in which particles and water peel off dirt layer by layer, can remove SR residue and LTCC plating inhibitor layers.

In addition, non-directional fine irregularities are formed on the surface, forming a highly adhesive base that is ideal for plating.

Uniform processing with the wide gun

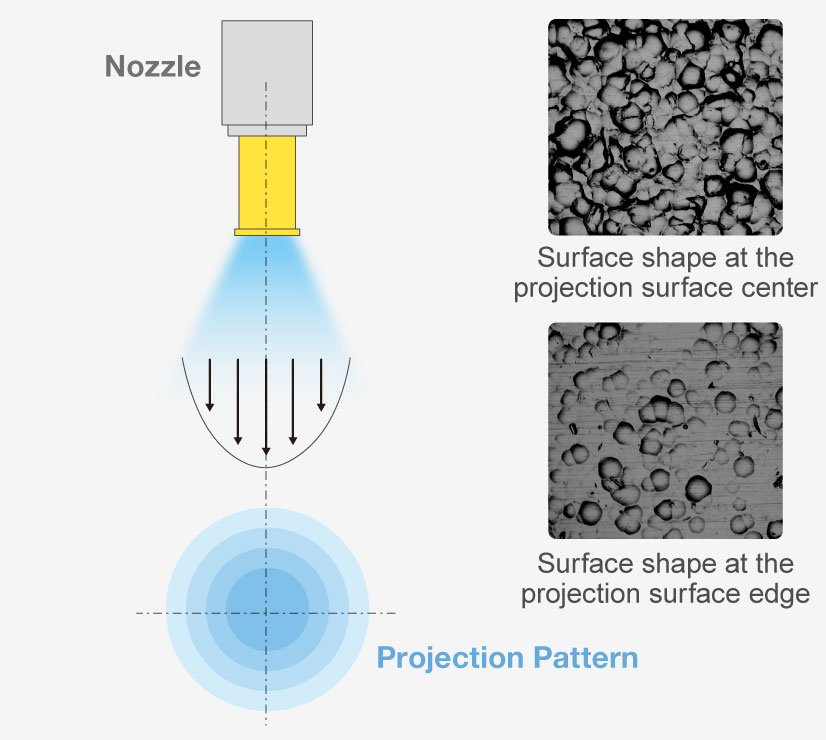

Conventional Gun

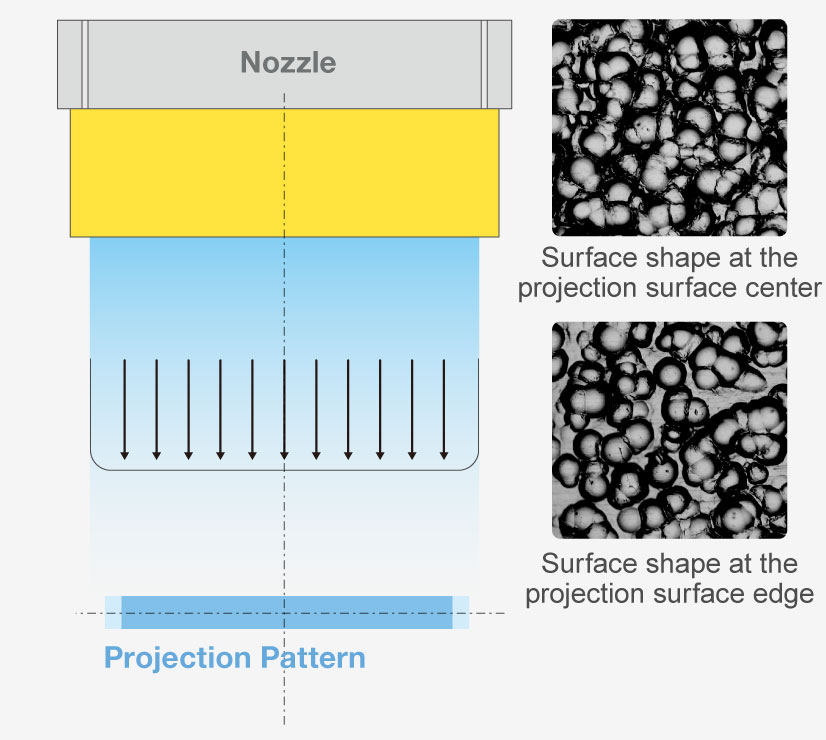

Wide Gun (our patented technology)

The wide gun, our original patented technology, has a slit-shaped nozzle cross-section and provides uniform processing power over the entire projection surface.

As shown in the figure above, with a conventional gun, the number of abrasive marks decreases as one moves away from the center of the projection surface, but with the wide gun, the number of abrasive marks is almost equal at both the center and at the edges. The high uniformity provided by this special gun enables even processing of the entire processing surface of wide workpieces.

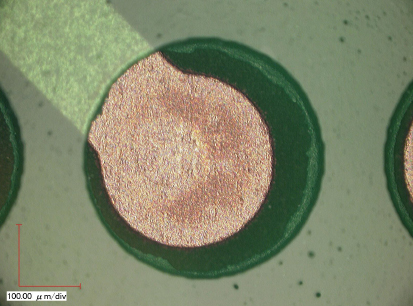

Example of cleaning to remove SR residue

Before Processing

After Wet Blasting

The roughened SR surface improves the wettability of the underfill and preflux.

Wet blasting removes the solder resist (SR) residue from land areas on the board surface as well as the oxide film that has formed on the circuit surfaces.

Fine irregularities are created in the wet-blasted areas, which increase wettability and improve adhesion.

Equipment Examples

We propose the following equipment according to the workpiece size and processing details. However, our equipment is essentially based on free design, in which the application and conditions are optimized for your company's processes. Our basic policy is to provide all our customers with optimal specifications. First, consult with us about the material and size of the workpiece, processing purpose, and equipment conditions. Our specialized staff will handle this.

Equipment for plate-shaped workpieces

- Automatic

Automatic equipment for plate-shaped workpieces and film mateiral and is capable of processing plate workpieces up to 600 mm wide.

Equipment for large-sized plate-shaped

- Semi-automatic

Wet blasting equipment with a large, wide gun for processing high-density mounting boards.

Equipment with an X-axis

- Semi-automatic

Automatic processing equipment that uses a single-axis wide gun to processes the entire surface of plate-shaped workpieces.