Thin-film coating pretreatment

Processing Details

- Roughening

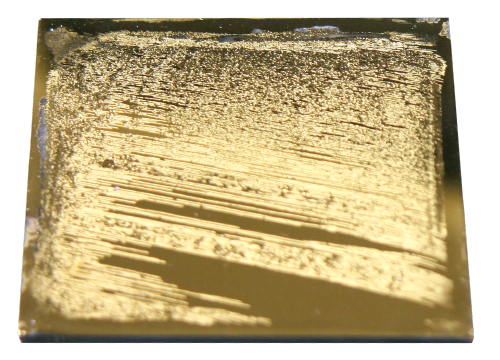

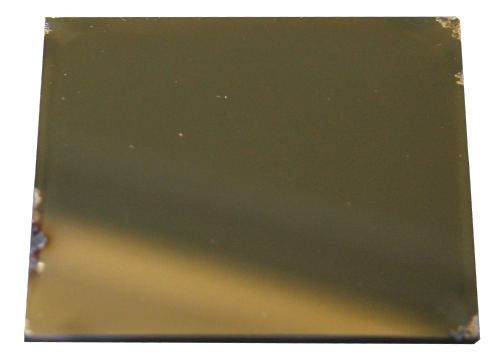

Ti coating film formation

Without pretreatment

Without pretreatment Film formed after wet blasting

Film formed after wet blastingWhat is "thin film coating pretreatment" by wet blasting?

When wet blasting is used as pretreatment for coating, a strong coating film can be formed on the surface by the anchor effect, which provides nano-level fine unevenness having no time dependency.

Wet blasting is a physical process and compatible with a wide range of organic and inorganic materials.

Four features of wet blasting

- No time dependency - There is no time dependency due to the wettability improved by surface area expansion.

- No deterioration - Since processing heat is not generated, no deformation or deterioration occurs.

- Nano anchor formation - Nano-level fine uneven surfaces are formed and an anchor effect can be expected.

- Fast batch processing - The etching rate is larger than that of other surface etching methods. The desired etching amount can be obtained in a short time.

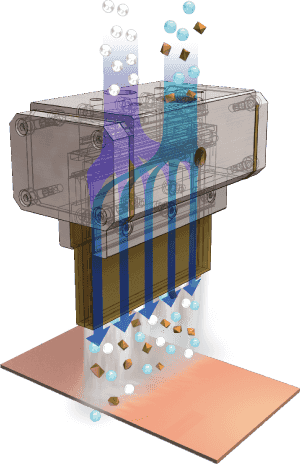

Wet Blasting Image

Wet blasting is a technique to project a mixture of abrasive and water at high speed with compressed air against a material to clean, process, and modify its surfaces. This technique allows fine abrasives to be used due to wet processing, and is good at forming a fine uneven surface while grinding the surface of the workpiece while silmutaneously removing dirt and foreign matter.

In addition, this chemical-free technique is eco-friendly and environmentally friendly, and it is also effective in reducing industrial waste.

For further information, see also "Introduction to wet blasting.”

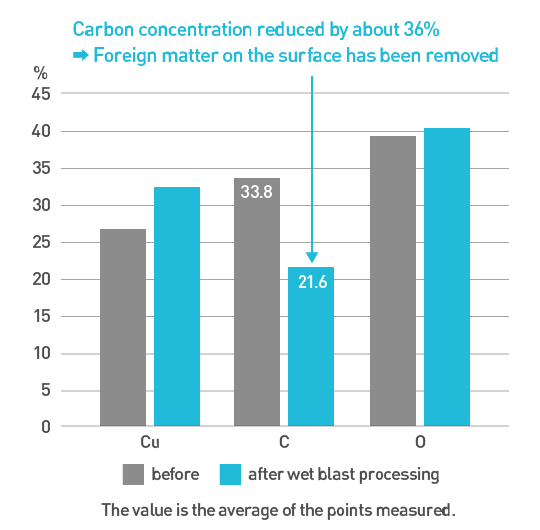

Evaluating the cleaning power of wet blasting

A comparison of untreated and wet-blasted surfaces shows that the amount of carbon (contamination) on the surface was reduced.

Comparison of element concentrations before and after wet blasting

Treatment Example

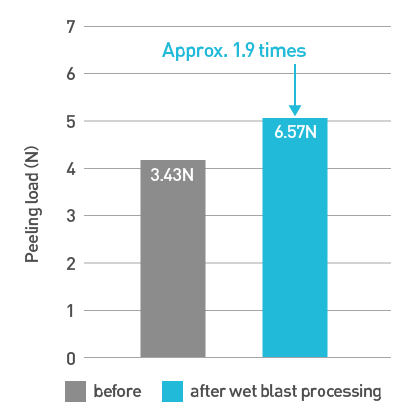

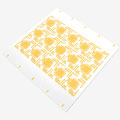

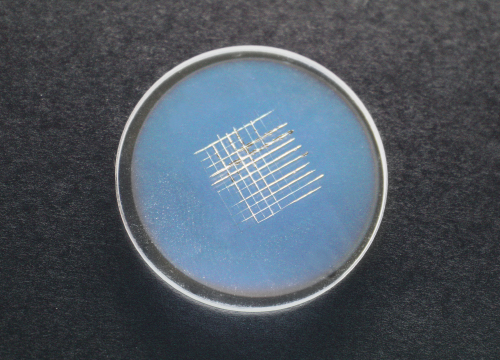

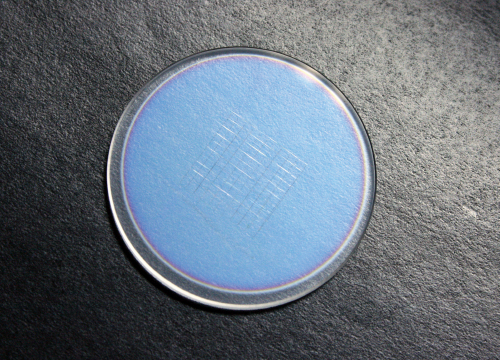

Glass x SiO2 Coating

Cross-Cut Test Results

Peeling / Without pretreatment

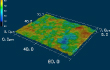

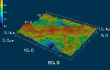

Peeling / Without pretreatmentRa 0.01 µm / RzJIS 0.14 µm

Without Peeling / Film formed after wet blasting

Without Peeling / Film formed after wet blastingRa 0.05 µm / RzJIS 0.37 µm

- Processing condition / abrasive: Polygonal alumina / Air pressure: 0.20 MPa

Processing Example

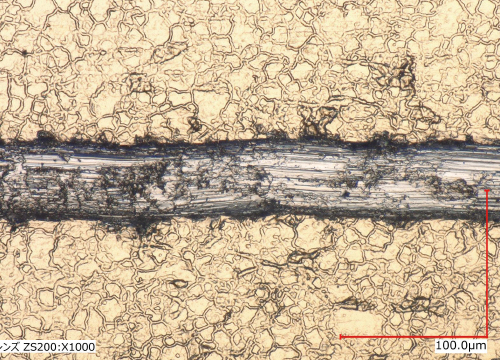

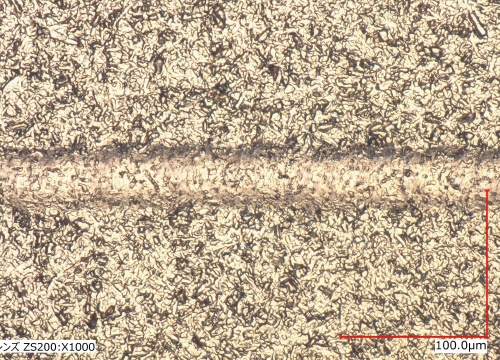

SUS×TiN Coating

Scratch Test Results

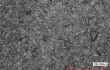

Untreated Workpiece

Untreated WorkpieceLoad: approx. 4.27 N (with peeling)

Wet blasted workpiece

Wet blasted workpieceLoad: approx. 4.27 N (without peeling)