Scraping of the build-up substrate

Processing Details

- Scraping

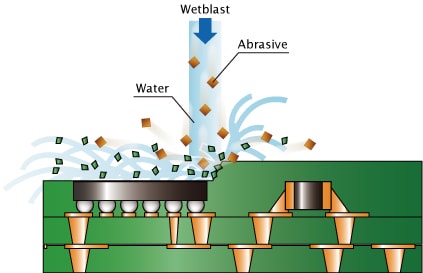

Fine surface processing by wet blasting

Physical processing, which allows the filler-containing resin layer on the build-up substrate surface to be processed uniformly at high speed.

Process Objective

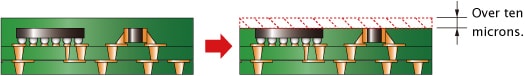

- Surface is exposed by removing a very thin layer of the surface of the substrate on which electric parts are embedded.

- Grinding of the resin on the surface of the substrate and only the circuits are left on it.

Problems with conventional processing methods

| Dry Etching (Plasma) |

|

|---|---|

| Laser |

|

| Machining |

|

Processing Image

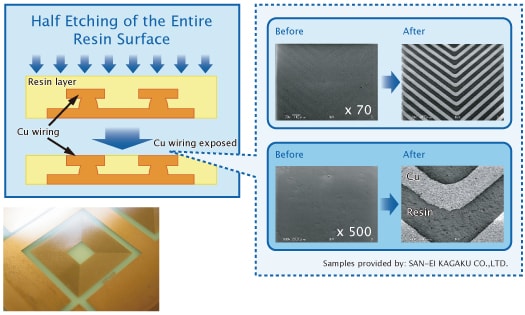

The Copper Wiring's Exposure According to Wet Blasting

Features

- Half-etching of the entire surface for the filler-contained resin.

- Process selection of the resin to reduce Copper etching.

Processing of undercoat materials

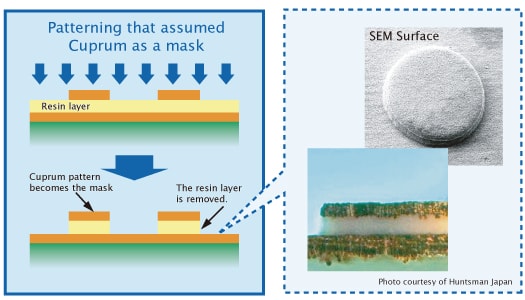

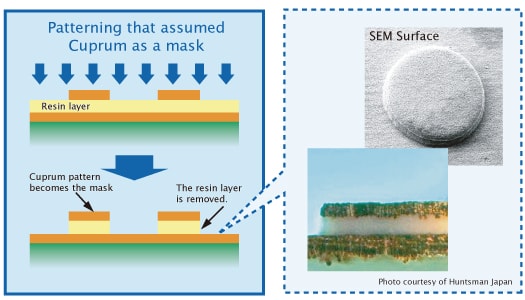

- Patterning using copper as a mask.

- High accuracy by anisotropic processing.

- Possible to alleviate (reduce) damage to conductors by processing with resin abrasives or super fine aluminum oxide abrasives.

Processing Condition

| Abrasive Used | Alumina A#2000 |

|---|---|

| Air Pressure | 0.25 MPa |

| Processing Speed | 20 mm/sec |

| Projection (Spray) Angle | 90° |

| Number of Passes for Processing | 4-10 passes |

Example of the formation of an embedded capacitor

- Patterning using copper as a mask.

- High accuracy by anisotropic processing.