Abrasives

The selection of abrasives (projection materials, media) in wet blasting is an extremely important factor in forming the desired surface condition.

We select and provide the most suitable abrasives in terms of material, shape, particle size, hardness, and cost that meet the processing conditions required by our customers.

If you would like a detailed explanation, please feel free to contact us.

Search by name

Search by abrasive material or shape

Ceramics: Polygonal

Main Uses

Cleaning, grinding, surface roughening, etc.

Material

Alumina, etc.

Particle Size Range

3-250μm

Ceramics: Spherical

Main Uses

Beautifying, cleaning, peening, etc.

Material

Glass, Zirconia, etc.

Particle Size Range

3-250μm

Resin

Main Uses

IC deflashing, paint removal, etc.

Material

Melamine, Phenol, etc.

Particle Size Range

80-500μm

Metal

Main Uses

Descaling, etc.

Material

Rust-proof high-chromium stainless cast steel

Particle Size Range

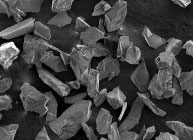

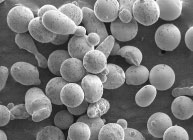

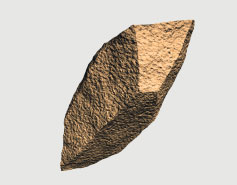

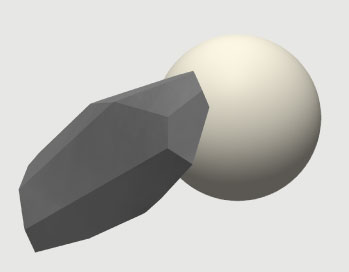

Abrasives|Ceramics: Polygonal

Images of Abrasive Shapes

Images of Abrasive ShapesAlumina and other polygonal particles have sharp protrusions and high grinding power. After processing, the surface has a narrow pitch with random uneven roughness with height differences. It is used for a wide range of applications, such as surface roughening,

Main Uses

Cleaning, grinding, surface roughening, etc.

Material

Alumina, etc.

Particle Size Range

3-250μm

Related page

Honing of Cutting Tool Edges

Related page

Substrate plating prewash

Related page

Thin-film coating pretreatment

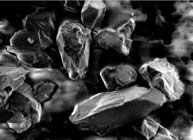

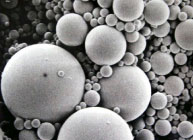

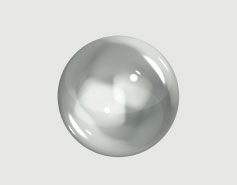

Abrasives|Ceramics: Spherical

Images of Abrasive Shapes

Images of Abrasive ShapesThey are spherical particles such as glass, zirconia, and alumina. By hitting or rubbing the object, the surface can be cleaned with almost no damage. Since the surface is covered with uniform dimples and has a semi-gloss finish after being processed, this process can be used for beautification as well. Another feature is the high peening effect achieved from the applied stress.

Main Uses

Beautifying, cleaning, peening, etc.

Material

Glass, Zirconia, etc.

Particle Size Range

3-250μm

Related page

Deburring of LED pacakages

Related page

Cleaning of critical parts for maintenance

Related page

Peening of airplane engine parts

Related page

Beautification of exterior parts

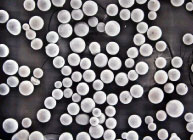

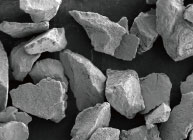

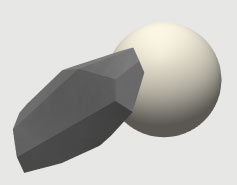

Abrasives|Resin

Images of Abrasive Shapes

Images of Abrasive ShapesThey are polygonal or spherical resin particles such as melamine and phenol resin. The main features are that the material is soft and the relative density is light. Since processing can be done with almost no damage to the workpiece, it is used for resin deburring, cleaning, and coating stripping of semiconductors as well as removal of support material from 3D-printed parts.

Main Uses

IC deflashing, paint removal, etc.

Material

Melamine, Phenol, etc.

Particle Size Range

80-500μm

Related page

Semiconductor resin deburring

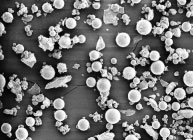

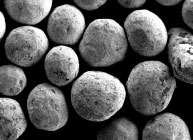

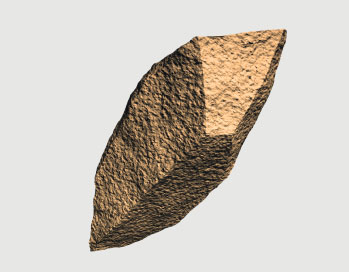

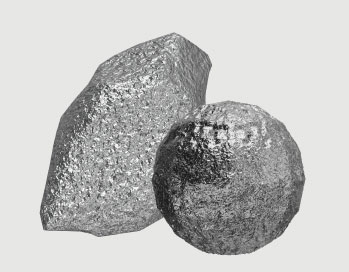

Abrasives|Metal

Images of Abrasive Shapes

Images of Abrasive ShapesThese are special stainless steel particles with high hardness and high relative density. Compared to ceramics, they have higher toughness and are less likely to chip or crack, so they have the advantage of lower consumption and less waste. They are used for the removal of oxide scale (descaling) and deburring.

Main Uses

Descaling, etc.

Material

Rust-proof high-chromium stainless cast steel

Particle Size Range

50-300μm

Related page