Coating pretreatment of cutting tools

Processing Details

- Washing

It improves the adhesion strength of the coating to the tools, enabling the production of high-quality cutting tools.

Wet blasting evenly removes dirt, foreign matter, brittle layers and other factors that prevent the coating from adhering, creating an optimal surface for coating. In doing so, it does not cause unnecessary damage to the cutting edge.

Wet blasting coating pretreatment for cutting tools

In cutting tool manufacturing, this pre-adhesion treatment uses wet blasting to remove impurities that adhere to the tool surface and inhibit the adhesion of the coating. This process exposes the pure surface of the tool surface and greatly improves the adhesion strength of the subsequent coating.

Main Processing Points

- It is possible to scrape off, clean and remove all kinds of contaminants such as release agents, oils, oxides, and brittle layers on the surfaces of cutting tools and dies by cleaning and scraping off only the outermost surface.

- Pulse processing with loose abrasives enables processing with minimal damage to the cutting edge.

- Even complex-shaped parts can be processed uniformly.

Problems with conventional processing methods

| Cleaning Process | Roughening & Grinding Processes | |

|---|---|---|

| Chemical Cleaning | Physical Polishing | Dry Blasting |

|

|

|

Features of Tool Coating Pretreatment with Wet Blasting

- The surface is scraped at the submicron level to remove various materials and their dirt and grime.

- This is a chemical-free physical cleaning method.

- Uniform cleaning is achieved because the fine particles follow the unevenness of the surface.

- Processing with loose abrasives prevents scratches on the target parts.

- Water cools the surface during processing, so no thermal deformation occurs.

- The water washes away particles and dirt while cleaning, so there is no dirt embedding or residue.

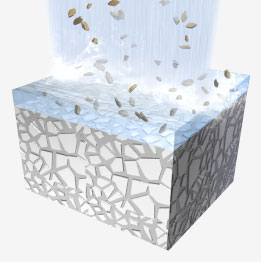

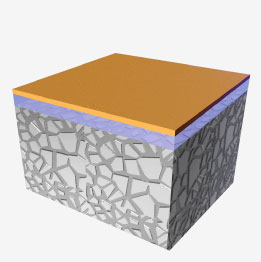

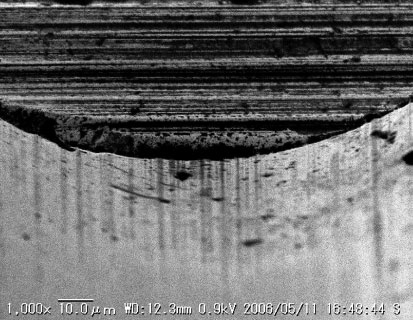

Before Coating

Contaminants such as oil and release agents and an unstable WC-Co (Tungsten Carbide Cobalt) layer with an uneven composition are present on the surface.

Image (Click to enlarge)

Examples of Applications and Applicable Products

| Applications | Examples of Applicable Products |

|---|---|

|

|

Processing Examples

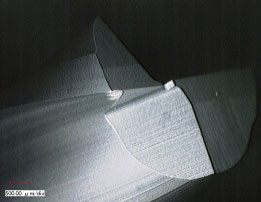

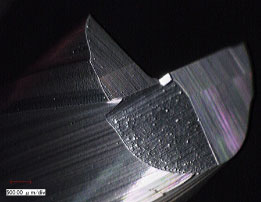

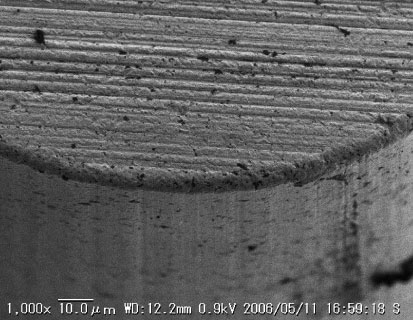

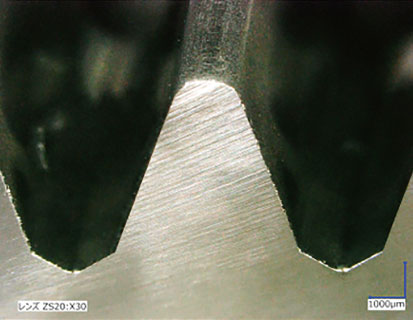

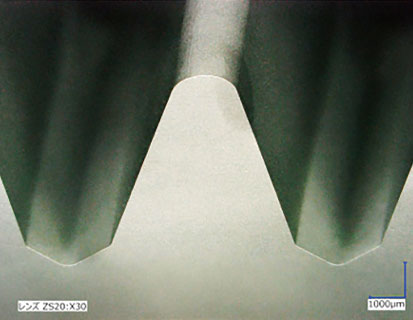

Cutting edge honing of cemented carbide tips

Before Processing

After Wet Blasting

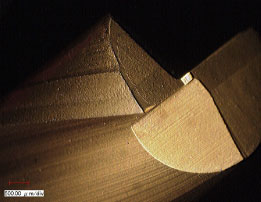

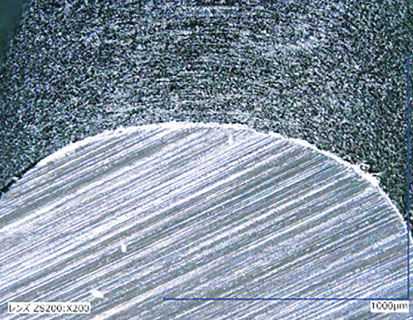

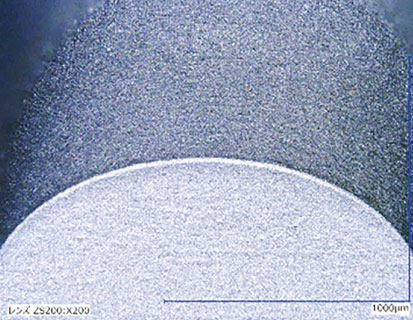

Hob Cutter Deburring

Before Processing

After Wet Blasting

Before Processing

After Wet Blasting

Equipment Examples

We propose the following equipment according to the workpiece size and processing details. However, our equipment is essentially based on free design, in which the application and conditions are optimized for your company's processes. Our basic policy is to provide all our customers with optimal specifications. First, consult with us about the material and size of the workpiece, processing purpose, and equipment conditions. Our specialized staff will handle this.

Equipment for cutting tools

- Automatic

Automatic machining equipment that performs high-precision cleaning and surface treatment of cutting tools, and R-honing and such of cutting edges.

Equipment for cutting tools

- Automatic

Wet blasting equipment for cutting tools that can automatically control the cutting edge shape (K-value).

Line-production equipment for cutting tools

- Automatic

Multi-gun type batch-processing equipment that performs surface treatment of cutting tools loaded in pallets.

Line-production equipment for cutting tools

- Automatic

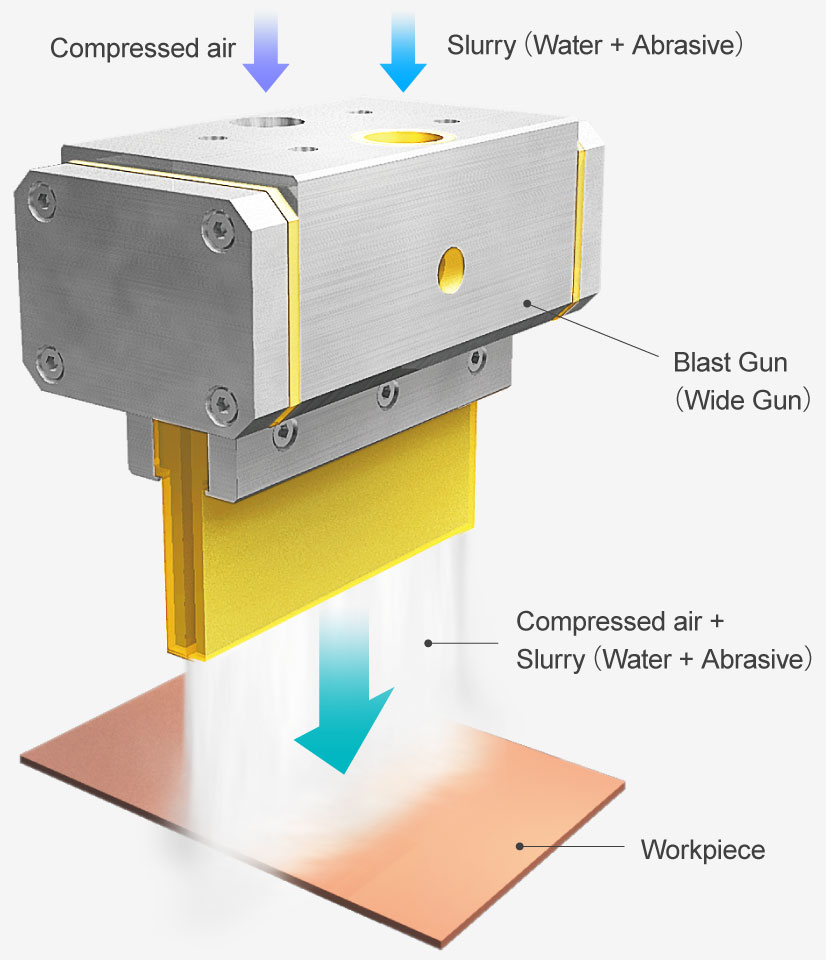

Equipment with a wide gun that does batch processing and performs surface treatment of cutting tools loaded in pallets.