Principle and Mechanism of Wet Blasting

This section describes the principle and mechanism of wet blasting technology.

Principle of Wet Blasting

Wet Blasting consists of three elements: abrasive, water, and compressed air.

Abrasives

We mainly use alumina, ceramics, glass, resin, and stainless steel, which do not dissolve in liquids, but we can also deal with sodium bicarbonate, which dissolves in water.

See below for details.

Water

Water is the biggest feature of wet blasting. It disperses the abrasives, sends it to the workpiece, washes it, prevents dirt from reattaching, and cools it and prevents static electricity.

Mainly, city water (tap water) or industrial water is used depending on the quality of the workpiece to be processed.

Compressed Air

Compressed air is used to accelerate the slurry mixture of abrasives and water and apply it to the target workpiece.

Basically, a range from 0.1 to 0.4 MPa can be set.

The accelerated slurry collides with the workpiece at the ultra-high speed of 60~100 m/s to perform processing.

Mechanism of Wet Blasting

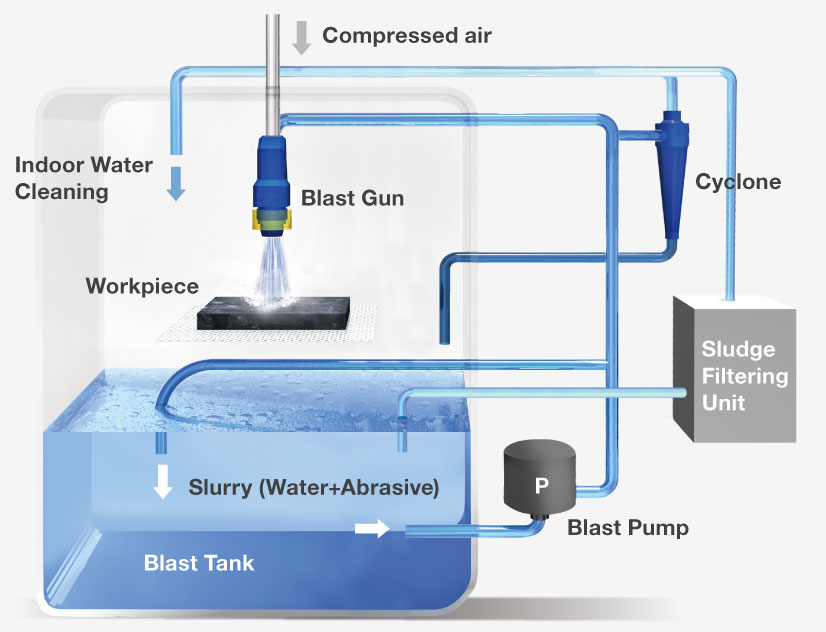

In wet blasting, abrasives and a liquid (mainly water) are mixed to create a "slurry" that looks like muddy water, which is projected by compressed air from a dedicated nozzle to process the target workpiece.

The slurry (abrasives + water) is sent from the blast tank to the blast gun by the blast pump, and using externally-supplied compressed air is projected onto the target workpiecet to be processed.

The sprayed slurry is then returned to the blast tank, where it is circulated and utilized.

This circulation structure keeps the waste and wastewater level low.

Furthermore, Macoho has developed highly durable core parts for its wet blasting equipment. Thus our equipment is ale to provide stable production and run continuously for long periods of time.