Main usages of Wet Blasting

Wet blasting is mainly used in the following applications.

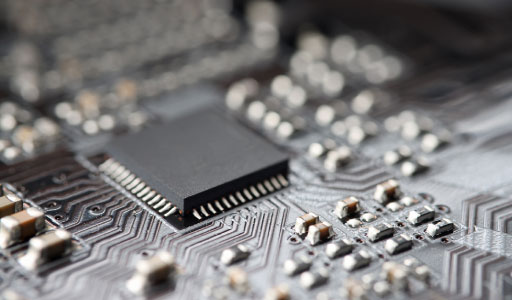

Cleaning

At the same time as the projected abrasive removes foreign matter on the surface, the water can wash the surface and clean the workpiece.

In reality, the abrasive scrapes off a thin layer on the surface together with the foreign matter at the submicron level, thus removing the attached foreign matter regardless of the material. By selecting the abrasive, you can do light to heavy cleaning of the part.

Related page

Related page

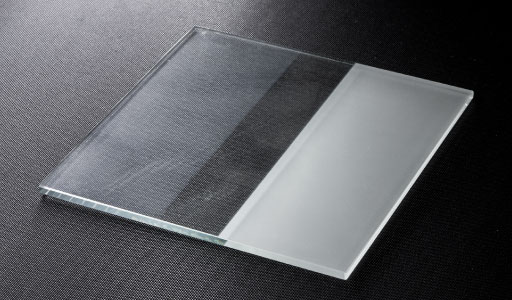

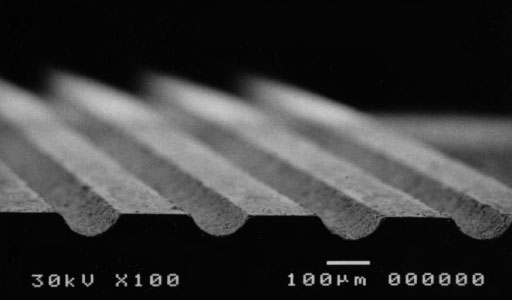

Roughening

For the purpose of improving surface adhesion, etc., fine unevenness can be added to the surface to create a satin finish (like a frosted glass surface).

By changing the abrasive, ithe peaks and valleys formed on the surface can be formed from 20 microns down to the sub-micron level.

Related page

Deburring

Since wet blasting, which is free-abrasive processing, can do processing using only the mass of the abrasives, scratches and dents don't occur, unlike fixed-abrasive processing such as grinding stones and belt ginders (polishers).

Utilizing this feature, burr removal (protrusions that occur when materials are cut or scraped, or excess protrusions that occur at the seams when molding using a die) from the workpiece can be done.

Related page

Related page

Related page

Scraping Off

It is possible to scrape off (strip off) only the surface material by using the difference in characteristics, such as the hardness of the underlying material and the surface material.

It is used for reworking bad production parts, maintenance work, etc.

Related page

Related page

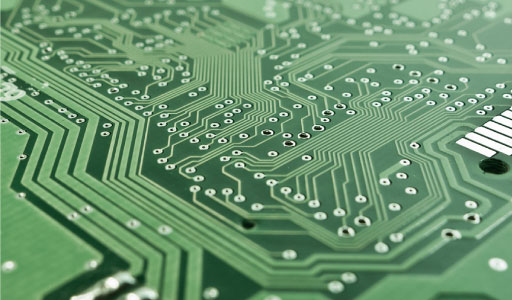

Etching

Etching usually refers to chemically scraping of the surface using chemicals and such. However, etching by wet blasting can be used to etch materials with high chemical resistance such as glass and ceramics, as well as composite materials where chemicals cannot be used.

Related page

Related page

Beautification

By adding fine unevenness to the surface, it is possible to perform decorative processing on the material's surface, such as giving it a satin finish (smooth glossy finish) or a dull finish (slightly glossy finish).

Related page