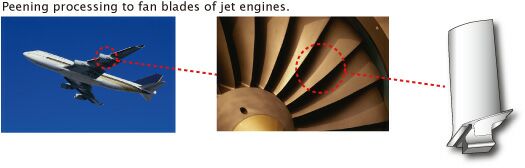

Peening of airplane engine parts

Processing Details

- Peening

What is Wet Peening?

The wet peening method is a new shot peening method, where wet blasting is used with a “wide gun,” our unique and patented wet blasting gun.

What is Peening?

This is a surface treatment by forging or peening; like hitting the metal surface with a round-head hammer.

Shot-peening is a surface treatment method for improving the mechanical characteristics of material surfaces by hitting innumerable spherical particles on metal surfaces:

- Applying residual compressive stress to the materials.

- Making plastic deformation and surface hardening to the work piece surface.

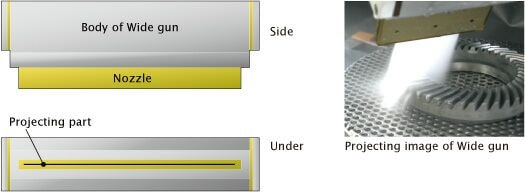

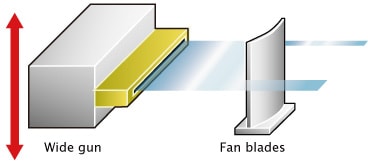

About our wide gun, the core technology of the wet-peening method.

- Slit-shaped nozzle cross section.

- Uniform processing power to the whole surface.

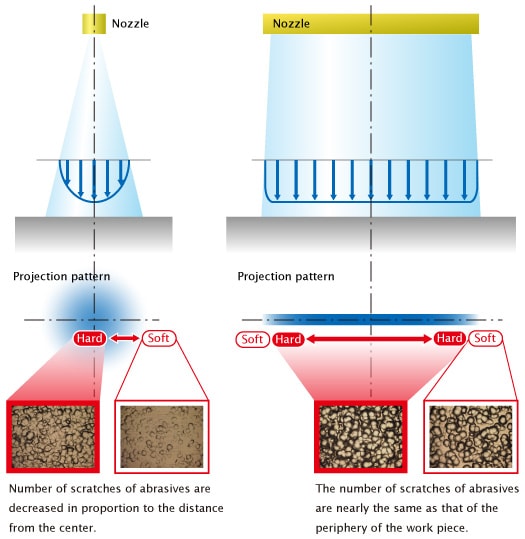

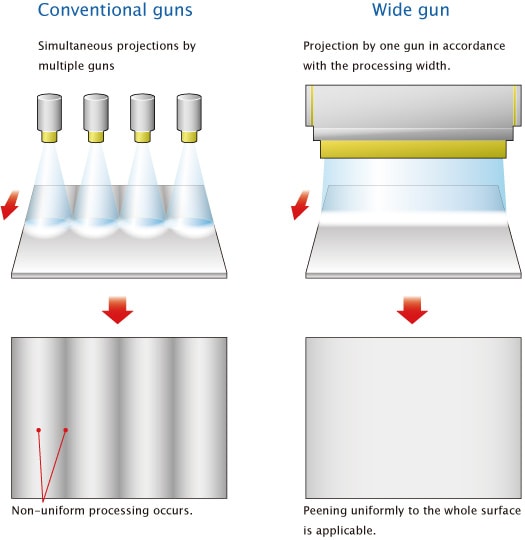

Differences compared with conventional guns/nozzles

Difference of projection patternsConventional Guns/Nozzles

Peening intensity is the strongest at the center and it becomes weaker as it comes to periphery area.

Wide Gun

Projection power is uniform to the whole area in the direction of slip length except for both ends.

Utilization Results

Processing Example

Treatment can be done equally to both sides of the fan-blade with the same peening strength.

For a large area treatment, huge reduction in processing time can be achieved by the use of the wide gun.