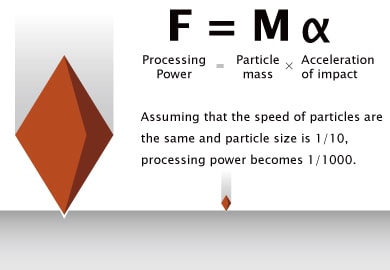

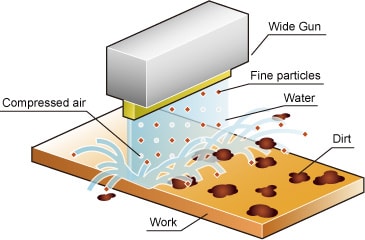

Less pressure onto the work piece is applied by continuous pulse processing to its surface.

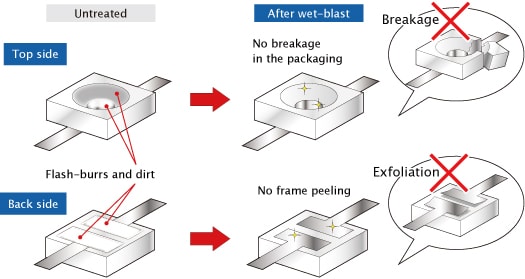

Deburring of LED pacakages

Processing Details

- Washing

- Removal

- Scraping

Process Objective

By removing the burrs and dirt from the LED package, deterioration of the reflection ratio of the reflecting surface can be prevented.

The point of contact between LED chip and die pad can be guaranteed.

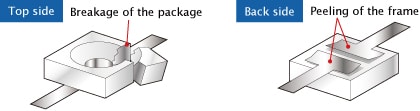

Problems related to burr removal

Separation of frame and resin as well as package breakage occur due to the high pressure of water-jet processing.

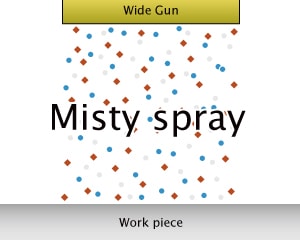

Processing Image

Wet Blasting Characteristics

1)By using precision physical cleaning, flash-burrs on the electrodes can be completely removed.

2)Soft processing using isolated abrasives makes it possible to reduce damage to the package.

3)It is possible to reduce damage to the package’s surface by using low-pressure super-fine abrasive processing.