Effects of Wet Blasting

The main effects of wet blasting are described below.

Cleaning

By using fine abrasives of several microns in size, foreign matter can be removed and cleaned without damaging the surface of the object, regardless of the material.

In addition, since wet blasting is a physical treatment, it can be applied to a variety of applications regardless of the workpiece or its material.

Application Examples

- Cleaning and pre-adhesion processing of anti-vibration parts

- Coating pretreatment of cutting tools

- Substrate plating prewash

- Deburring of LED pacakages

- Maintenance of plant equipment

- Substrate Desmearing

- Dross removal after laser processing

- Decontamination

- Restoration of automobile and motorcycle parts

- Cleaning of AT Separators

- Removal of die-release material

- Deposition Jig Cleaning

Removal

It can remove dirt and oxide film from the surface of the target workpiece.

Because of its degreasing and surface activation effects, it is used as a pretreatment for adhesion, coating, plating, and painting.

Application Examples

- Semiconductor resin deburring

- Black scale removal and part lubrication for cold forging

- Deburring of LED pacakages

- Turbofan Deburring

- Deburring of Medical Forceps

- Paint stripping of engine exterior parts

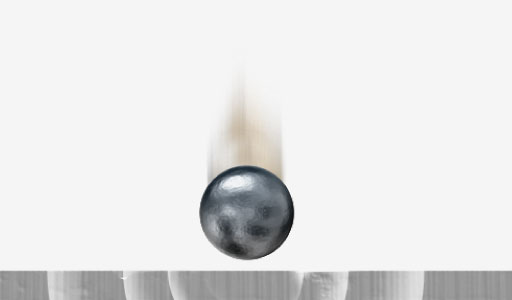

Peening

Our original nozzle enables uniform treatment over a wide area. At the same time, a unique texture specific to this method can be obtained.

It is also used for shot peening. But because fine particles can be used for wet blasting, it has the advantage of being highly effective in cooling the processed surface and less likely to cause surface stress release (hardness reduction).

Application Examples

- Peening of airplane engine parts

- Beautification of exterior parts

- Restoration of automobile and motorcycle parts

- Air Cylinder Surface Beautification

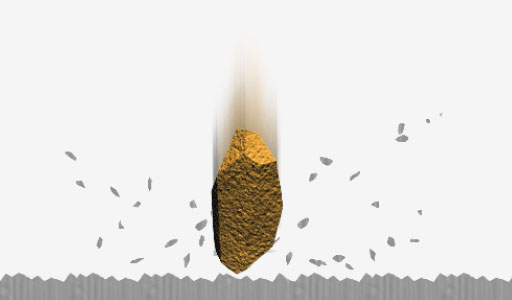

Roughening

Since wet blasting can use fine particles of several microns in size, it forms a dense and uniform roughness.

In addition, because it is a physical treatment, it can be used for various applications regardless of the workpiece or its material.

Application Examples

- Cleaning and pre-adhesion processing of anti-vibration parts

- Black scale removal and part lubrication for cold forging

- Improvement of underfill wettability

- Restoration of automobile and motorcycle parts

- Air Cylinder Surface Beautification

Shaving

With the high degree of control through its fluid operation that is unique to wet processing, various types of processing from fine grinding to hard processing can be performed.

Application Examples

- Honing of Cutting Tool Edges

- Scraping of the build-up substrate

- Black scale removal and part lubrication for cold forging

- Paint stripping of engine exterior parts