Honing of Cutting Tool Edges

Processing Details

- Scraping

Controls the cutting edge shape of the cutting tool with a high accuracy of ±5%.

Honing cutting tool edges using wet blasting is a highly accurate and consistent process, enabling the manufacture of high-added-value cutting tools.

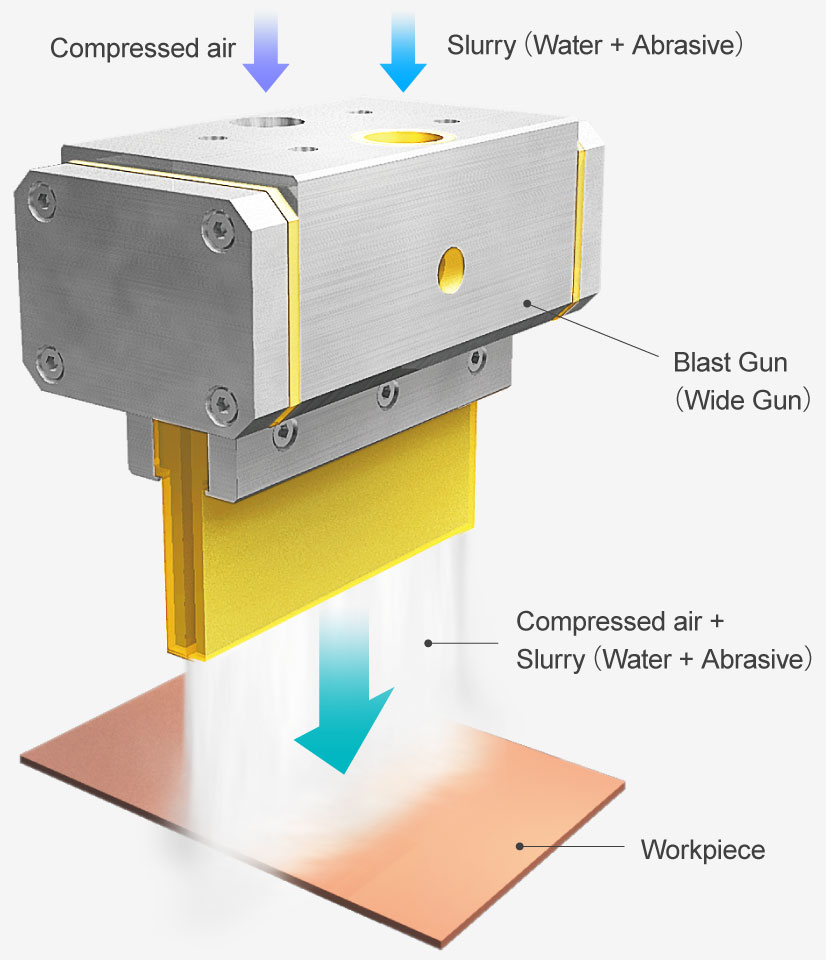

Cutting tool edge honing with wet blasting

Burrs that occur on the cutting edge during the manufacturing of cutting tools (inserts, etc.) are removed by wet blasting, and by giving the cutting edge a radius (cutting edge honing), chipping is prevented. This enables stable production of high-quality products with a long life and no variations. At the same time, this process is also effective in improving the adhesion strength of the coating on the cutting edge.

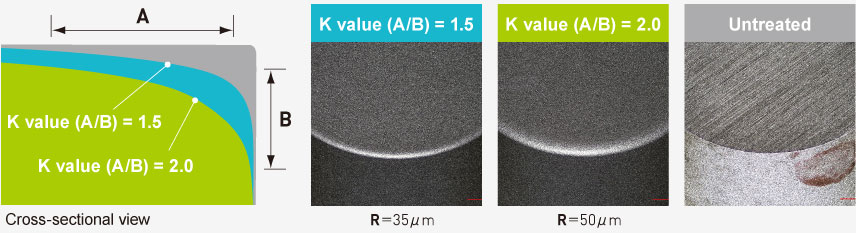

Another feature of our equipment is the easy control of K value (cutting edge shape).

Processing Points

- The cutting tool life can be extended up to 3 times by adding a radius to the cutting edge.

- Complex shapes can also be processed uniformly.

- K value (A/B ratio) can be controlled from 1.0 to 2.0 by controlling the rake face and flank face R ratios.

- High-precision processing of ±5% is possible with fine abrasives

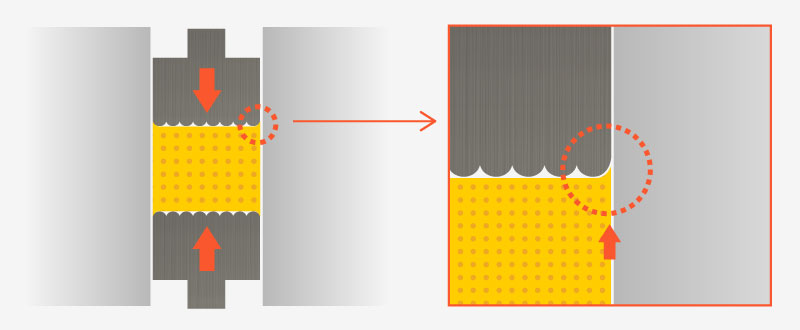

Problems with press forming of cutting tools

- Burrs occur in the gap between the dies.

- The coating peels off from the tip of the cutting edge.

- The cutting edge radius varies after honing.

Wet Blasting Images

After Press Molding

Press molding produces burrs in the gap between the dies.

Untreated

Burrs increase the chance of the edges chipping and breaking.

After Wet Blasting

By removing burrs from the cutting edge and adding a radius, chipping is prevented. This enables uniform coating all the way to the tip of the cutting edge, thereby extending the tool life.

Processing Examples

Edge honing of cemented carbide tips

Before Processing

After Wet Blasting

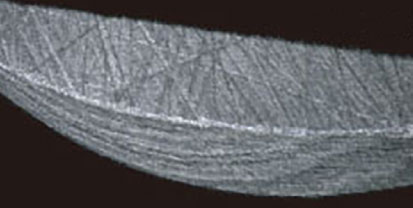

Before Processing

After Wet Blasting

Controlling the K value of cemented carbide tips

Equipment Examples

We propose the following equipment according to the workpiece size and processing details. However, our equipment is essentially based on free design, in which the application and conditions are optimized for your company's processes. Our basic policy is to provide all our customers with optimal specifications. First, consult with us about the material and size of the workpiece, processing purpose, and equipment conditions. Our specialized staff will handle this.

Equipment for cutting tools

- Automatic

Automatic machining equipment that performs high-precision cleaning and surface treatment of cutting tools, and R-honing and such of cutting edges.

Equipment for cutting tools

- Automatic

Wet blasting equipment for cutting tools that can automatically control the cutting edge shape (K-value).

Line-production equipment for cutting tools

- Automatic

Multi-gun type batch-processing equipment that performs surface treatment of cutting tools loaded in pallets.

Line-production equipment for cutting tools

- Automatic

Equipment with a wide gun that does batch processing and performs surface treatment of cutting tools loaded in pallets.