Semiconductor resin deburring

Processing Details

- Removal

Removes fine burrs without damaging the resin surface.

Deburring by wet blasting, which uses a fine abrasive a few microns in size, enables damage-free processing with no package breakage or internal chip peeling. It also features high controllability, enabling stable quality processing at a relatively low cost.

Precision resin deburring (deflashing) with wet blasting

This surface treatment technology removes burrs generated during the molding of semiconductor packages such as power devices using thermosetting resins such as epoxy resins without damage, and performs a plating pre-treatment.

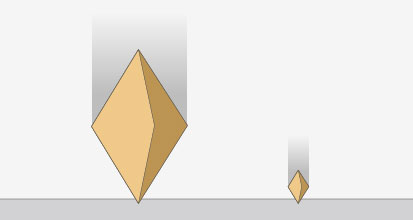

Types of Burrs

Dam Burrs

Burrs that fill out between the leads.

It is possible to remove burrs by conventional burr removal methods.

Side Burrs

Thick burrs on the side of the leads.

It is possible to remove burrs by conventional burr removal methods.

Flash Burrs

Thinner burrs on leads and heat sinks.

Demand for the removal of flash burrs is increasing due to the technical trends of smaller packaging and thinner products. Therefore a burr removal method with a reasonable price and stable quality is needed.

Benefits of flash burr removal by wet blasting

- Stable quality deburring can be done at a low cost.

- No package damage or internal chip peeling.

- It does not roughen the package surface.

Problems with resin deburring

- You want to stop using a chemical process (electrolytic pretreatment + water jet).

- Internal damage to the semiconductor package and peeling at the interface between the lead frame and the sealing resin occur.

- The package is small and burrs are difficult to remove.

- Excessive scraping of the resin surface.

- Poor plating adhesion after deburring.

Advantages of resin deburring with wet blasting

- No electrolytic pretreatments or other chemicals are used.

- High-speed processing is possible by using particles appropriate for each type of burr.

- Possible to only process the targeted sections, such as the leads.

- Easy pressure control.

- Fine particles can be used.

- No dust is generated.

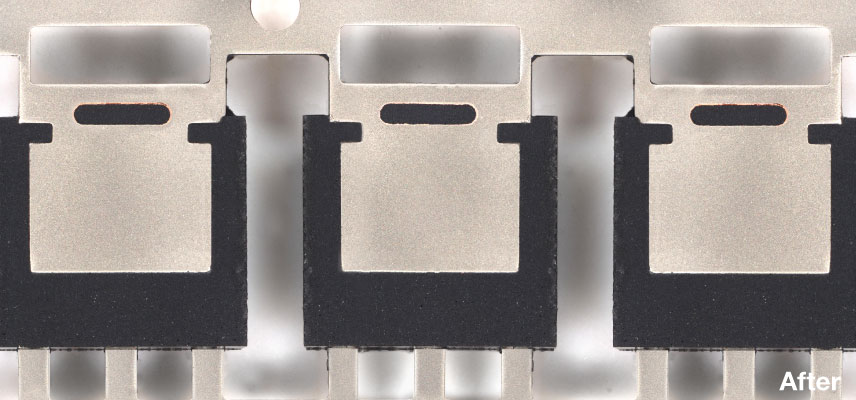

Wet Blasting Features

By precision physical cleaning, flash-burrs on the electrode plane can be completely removed.

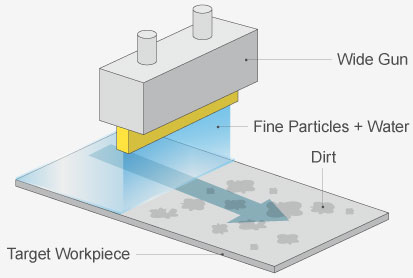

Using the energy of the water and abrasives colliding with the surface, dirt and foreign matter are removed while simultaneously scraping off the surface of the part.

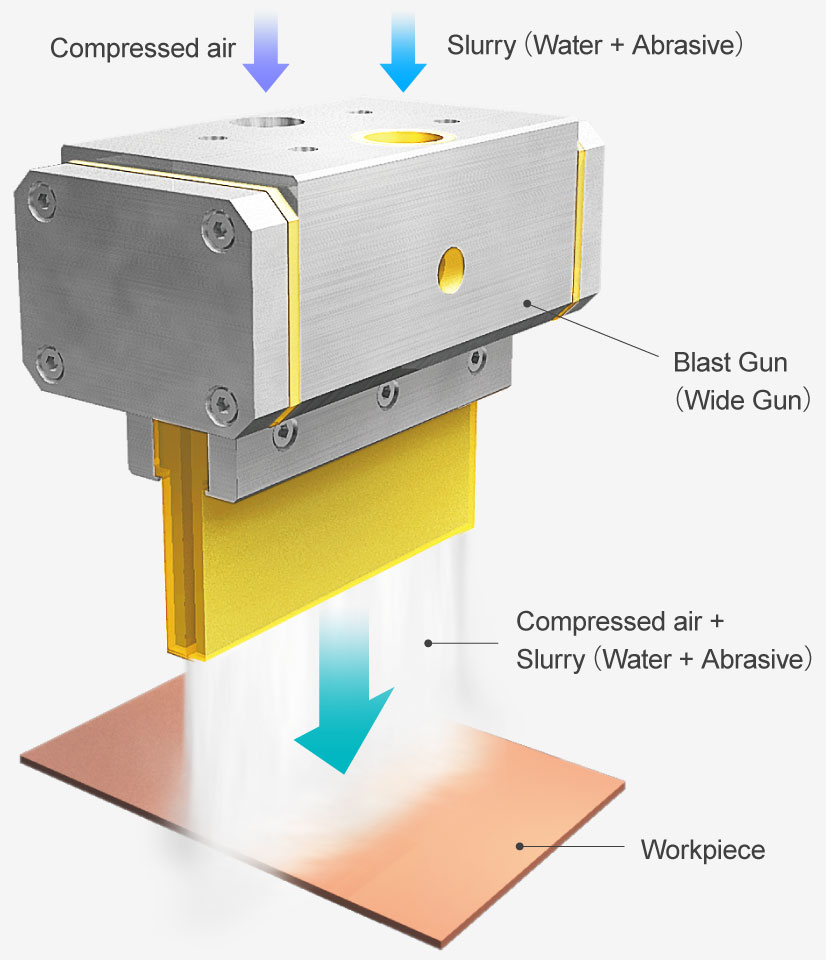

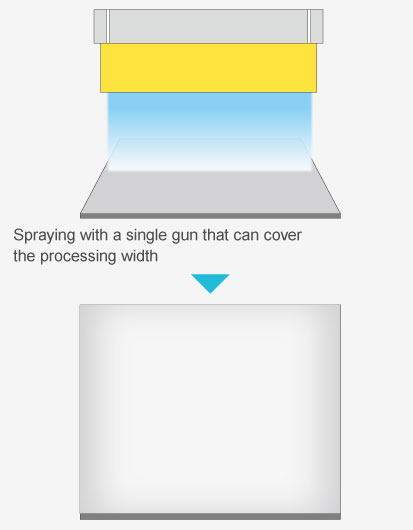

By using Macoho's original and patented wide gun, non-uniform processing is reduced.

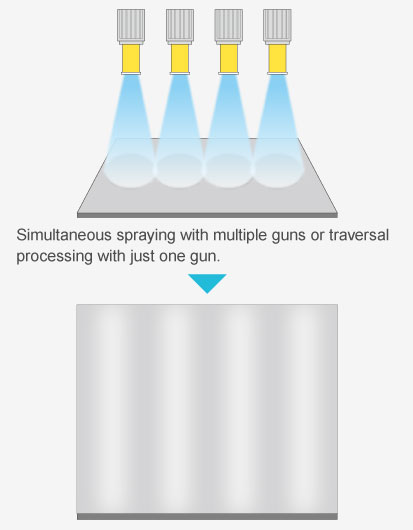

Conventional Guns (nozzles)

Non-uniform processing occurs

Wide Gun (our patented technology)

It is possible to uniformly process the whole surface

Soft processing using loose abrasives makes it possible to reduce damage to the package

In wet blasting, compressed air sprays the fine particles and water onto the workpiece in a mist form. Therefore, the surface of the workpiece is processed in a continuous pulse-like manner, and the pressure applied during this process is extremely small.

Low-pressure processing using fine particles enables processing with minimal damage to the package surface.

F=Mα

(Processing Power) = (Mass of the Particles) x (Collision Acceleration)

*When the particle velocity is the same, the processing force is 1/1000th when the particle diameter is 1/10th.

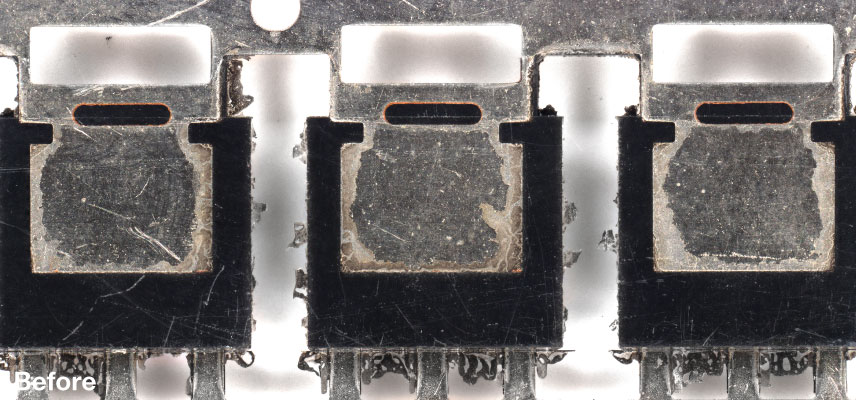

Resin Deburring (Deflashing) Examples

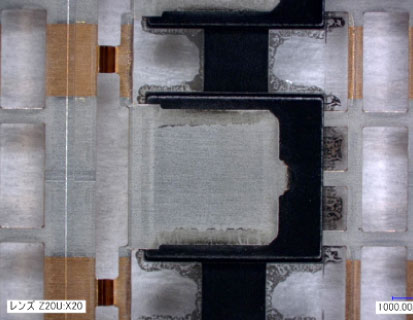

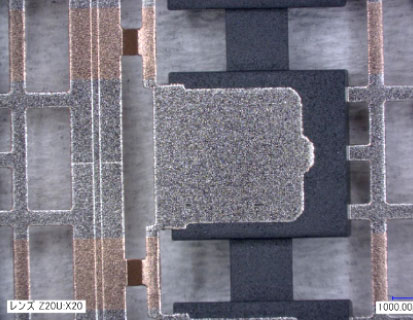

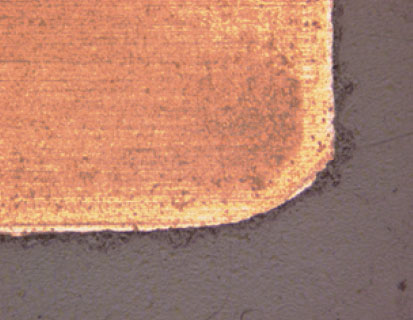

Removal of strong burrs from lead frames

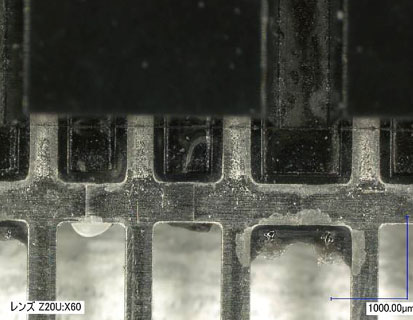

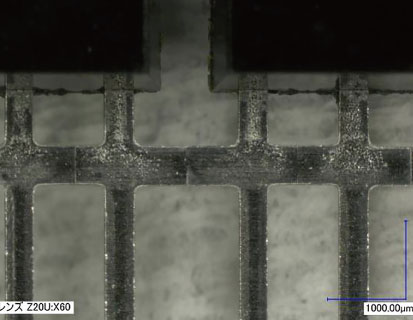

Before Processing

After Wet Blasting

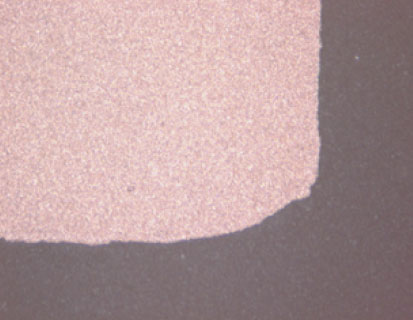

Flash burr removal from heat sink surface

Before Processing

After Wet Blasting

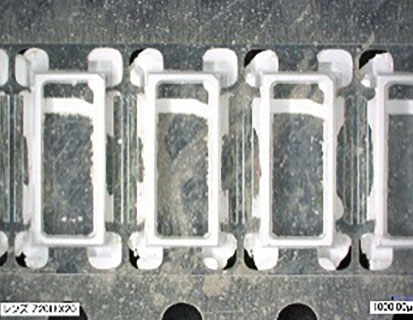

Removal of dam burrs and side burrs

Before Processing

After Wet Blasting

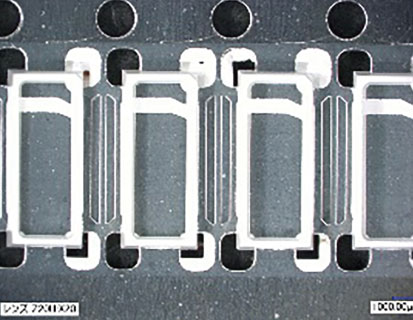

Removal of dam burrs

Before Processing

After Wet Blasting

Equipment Examples

We propose the following equipment according to the workpiece size and processing details. However, our equipment is essentially based on free design, in which the application and conditions are optimized for your company's processes. Our basic policy is to provide all our customers with optimal specifications. First, consult with us about the material and size of the workpiece, processing purpose, and equipment conditions. Our specialized staff will handle this.

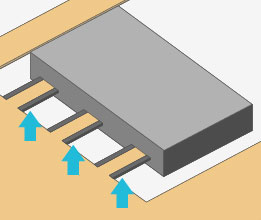

Equipment for plate-shaped workpieces

- Automatic

Compact automatic equipment for simultaneous double-sided processing of lead frames and other thin plate-shaped workpieces.

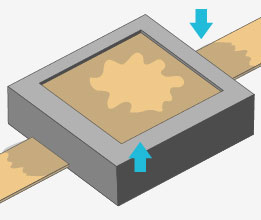

Equipment for research and development

- Semi-automatic

Compact equipment suitable for research and development that automatically processes workpieces by using a wide gun on a single axis.

Related Pages

Please click here for content related to the examples shown here.