Improved adhesion for difficult-to-adhere resin materials

Processing Details

- Washing

- Roughening

Improved adhesion strength by up to 2.5 times with minimal dielectric loss

Wet blasting pretreatment improves the plating adhesion strength of difficult-to-adhere resin materials (PI, LCP, PET, and others). In addition, while increasing adhesion strength, it is also possible to form a "low roughness surface" with no transmission loss for electronic components.

For difficult-to-adhere resin materials

What are difficult-to-adhere resin materials?

As the name suggests, difficult-to-adhere materials are "materials that are difficult to bond."

In particular, many synthetic resins (so-called plastics), such as polyimide (PI), modified polyimide (MPI), polyethylene (PE), polyethylene terephthalate (PET), polypropylene (PP), silicone rubber, polyacetal, and fluoropolymer (FR) are considered to be difficult-to-adhere materials.

In addition, super-engineered plastics such as liquid crystal polymer (LCP), PPS resin, and PEEK resin have similar characteristics.

These are generally referred to as "difficult-to-adhere resin materials" on this page.

Problems and characteristics of difficult-to-adhere resin materials

These difficult-to-ahere resin materials, such as polyimide (PI), naturally present challenges for improving bond strength during bonding to other materials and during plating.

On the other hand, each of the above difficult-to-adhere resin materials has its own inherent high performance. Examples include heat resistance, flame resistance, low water absorption, and formability. In addition, there are cases where this "difficult-to-adhere" characteristic is utilized (example: fluoropolymers in frying pans).

Wet blasting improves adhesion strength of difficult-to-adhere resin materials.

One of the reasons why these difficult-to-adhere resin materials are "difficult to bond" is due to the "wettability" (hydrophilicity, hydrophobicity) of the material.

Wet blasting can increase wettability for a variety of reasons, and is used to improve adhesion strength in many dissimilar material bonding applications.

Issues related to difficult-to-adhere resin materials in electronic components

These hard-to adhere resin materials are also used in many electronic components. But there may be several problems with this.

(Problem) Difficult-to-adhere resin materials with low dielectric loss are difficult to bond to.

Electronic components, especially those that handle high-speed signals, generally use materials with low dielectric loss.

However, these materials with low dielectric loss (low dielectric constant materials) are difficult-to-adhere resin materials, and as mentioned above, bonding these materials is often relatively difficult.

(Problem) Transmisson loss increases with micron-sized irregularities.

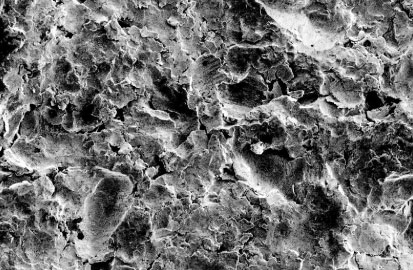

In order to improve adhesion strength during plating, a pretreatment method is used to roughen the surface of the target resin, such as PI, to form minute irregularities.

However, if the unevenness (roughness) formed in this process becomes too large, transmission loss increases, and in some cases, the required dielectric constant cannot be obtained.

We propose the following "wet blasting adhesion pre-treatment" to address the above issues of "difficult-to-adhere resin materials in electronic components".

Adhesion pretreatment by wet-blasting

Wet blasting creates dense submicron irregularities with particles of several microns in size, improving the adhesion of plating on these difficult-to-adhere resin materials by up to 2.5 times while maintaining surface roughness.

Wet blasting pre-treatment can solve the above-mentioned problems of difficult-to-adhere resin materials in electronic components by "minimizing dielectric loss" and "improving adhesion strength".

Processing Features

Gives Uniform Unevenness

Our original "wide gun" enables uniform treatment of a wide area.

Because it is physical processing, any material can be processed.

Wet blasting is a physical process, so it does not matter what material is being processed.

Dense roughening with fine particles

Wet blasting can use fine abrasives (from 3 microns) that sandblasting cannot handle. Therefore, it is possible to form submicron-sized fine irregularities.

No organic solvents or chemicals are used.

Because it is a physical process, no chemicals are needed. In addition, dust that can be a problem with sandblasting is extremely low, so you can expect a clean working environment.

For more information on the wet blasting process, see "What is Wet Blasting?"

Test Data

We have a proven track record in improving adhesion strength for PI, LCP, and PET materials with wet blasting.

Please feel free to contact us for details on test data and applications for other difficult-to-adhere resin materials.

Equipment Information

Please click here for information on equipment related to the examples shown here.

Related Pages

Please click here for content related to the examples shown here.